Features:

1. Using American ultrasonic technology, double-head high-power transducer; microcomputer processing control, real-time automatic frequency tracking, current and voltage detection, to ensure stable work.

2. Full touch screen microcomputer control processing system, the adjustment of various parameters is very convenient and accurate;

3. Most of the components are imported with original packaging, and the transducers imported from the United States have high energy conversion and utilization efficiency;

4. The circuit is equipped with multiple automatic protection devices such as power, excessive current, frequency offset, and welding head wear to ensure the stability of the equipment;

Welding principle:

Metal welding is to use high-frequency vibration waves to transmit to two metal surfaces that need to be welded.

Under pressure, two metal surfaces rub against each other to form fusion between molecular layers,

Its advantages are fast, energy-saving, high fusion strength, good electrical conductivity, good thermal conductivity, no sparks, and close to cold state.

Advantages of welding:

1. Ultrasonic wire harness welding does not need to use solder grease and flux, and has low requirements on the surface of the workpiece to be welded, and can be welded with oxidation, electroplating, and low flatness.

2. The tool head has a longer service life, which is better than crimping, soldering or resistance welding.

3. The conductive resistance of welding products is extremely low, basically zero resistance.

4. The machine is small in size and light in weight; the cost of use is extremely low, and the welding cross section can be welded from 0.2 square millimeters to 40 square millimeters.

5. The equipment is easy to use, no skilled workers are needed, and it only takes a few minutes of training.

6. There is no spark in welding, which is close to cold welding.

Ultrasonic metal welding applicable products:

1), nickel metal hydride battery nickel metal hydride battery nickel mesh and nickel sheet mutual melting and nickel sheet mutual melting. .

2), lithium battery, polymer battery copper foil and nickel sheet mutual melting, aluminum foil and aluminum sheet mutual melting. .

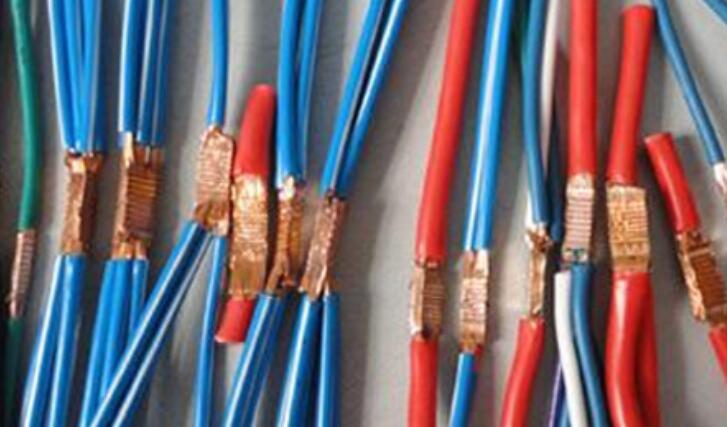

3) The wires fuse together, and one or more wires fuse together.

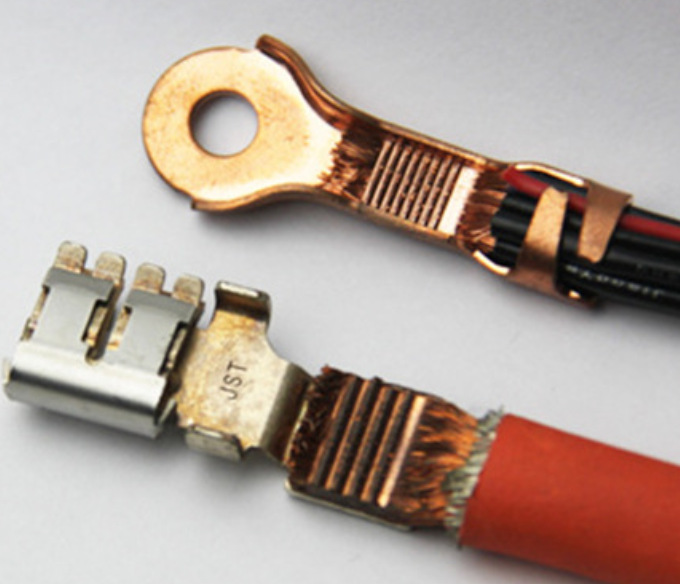

4), wires and various electronic components, contacts, connectors fuse each other.

5) Famous home appliances, large-scale heat sinks for automobiles, heat exchange fins, and mutual melting of honeycomb cores.

6), Electromagnetic switch, non-fuse switch and other large current contacts, mutual fusion of dissimilar metal sheets.

7) The sealing and cutting of the metal pipe can be watertight and airtight.

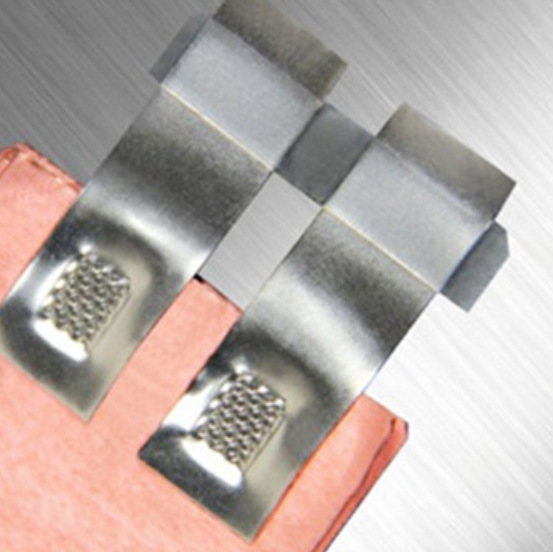

Single-strand, multi-strand enameled wire, tinned copper wire, welding between metal terminals, automotive wiring harness, electrical wiring harness welding, motor wiring harness welding, automotive wiring harness, relay, motor vehicle copper wiring harness, automotive wiring harness terminal, motorcycle wiring harness, electric Car wiring harness, multi-strand wire and cable, electrical connector wiring harness, electrical terminal block, solid copper wire and rare metal alloy wire, copper alloy wiring harness, engine wiring harness, motor wiring harness, airbag wiring harness, metal braided wire, metal twisted wire Combining wires, battery wires, multi-strand copper wires, motor leads, cables, terminal connection wires, sensor connection wires, computer interface connection wires, wire harnesses and thin rods, copper wire lead-out wires and other products. Copper wire harness, aluminum wire harness, copper alloy wire harness, automotive wire harness, wire, wire, cable wire, copper lead wire, lead wire, connecting wire, copper stranded wire, copper stranded wire, battery wire, copper braided wire (copper braided wire) and Terminals, copper sheets, end pieces, copper sheets, and electronic components are welded together. Welding of various automotive copper and aluminum wire harnesses, relays and other precision metal parts; copper and aluminum wires, cables, copper stranded wires, copper braided wires (copper braided wires) ) welding with metal terminals; welding of wires or thin cables and automotive airbag wires. Mesh welding: Ultrasonic metal welding usually designs reticulation on the surface of the welding position and the surface of the base. The purpose of the reticulation design is to prevent the sliding of metal parts. The reticulation design generally has square, rhombus and strip reticulation. Gold jewelry and other metal-clad welding heads and bases cannot be designed with textures according to the requirements. The size and depth of the texture are determined according to the specific welding material requirements. Metal wire harness terminal welding machines are widely used in automobiles, motorcycles, electronics, motors, Electrical appliances, solar energy, batteries, computers, communication equipment, instruments, hardware and other industries.

Addr:Building A10, Xiawei Commercial and Residential Area, Fengqing Road, Fenggang Town, Dongguan City

Tel:0769-87559708 24小時技術(shù)支持電話:13602300129

Email:lbcsb@163.com lbcsb@126.com